Fruit juice production, one of the cornerstones of today’s food industry, is shaped by innovative technologies and efficient production lines. Modern fruit juice production line machines, in particular, offer producers fast and efficient production processes, increasing quality and reducing costs. In this article, we will discuss the main machines and systems used for fruit juice production, and we will also explain how each technology contributes to the production process.

Conveyor: Efficient Material Handling

One of the first steps in the juice production line is the transportation of raw materials before processing. The Z-type conveyor is an important machine that comes into play at this stage. This conveyor system allows the fruits to be easily transported to the production line. The design of the Z-type conveyors is particularly suitable for vertical transportation. In this way, space is saved and maximum efficiency is achieved in the production area.

The biggest advantage of the Z-type conveyors is that the materials are transported quickly and safely. In addition, the production time is shortened thanks to the fast operation of these systems, which allows businesses to produce more. Conveyor systems also ensure that the fruits are carefully sorted and arranged before being transported to the washing and processing stages.

Universal Washer: Cleaning and Hygiene

Hygiene is of great importance in fruit juice production. Fruits must be processed fresh and clean. The universal washing machine comes into play at this stage. This machine cleans the dirt, soil and other foreign substances on the fruits. Universal washing machines ensure that all contaminants on the surface of the fruits are effectively removed by using water and high-pressure air flows.

In addition, some modern washing machines are equipped with special systems that help to clean pesticides or other chemicals that may remain on the fruits. In this way, the quality and safety of the products to be offered to the consumer is increased.

Sorting Table Machine: Selective Process for Excellent Quality

In fruit juice production, only quality and healthy fruits should be used. The Sorting Table Machine that comes into play at this stage is used to control the quality of the fruits. In the Sorting Table Machine, workers or automatic machines examine the fruits and sort out those that are damaged, spoiled or have undesirable characteristics.

This system directly affects the quality of the fruit juice production line. Thanks to the Sorting Table Machine, only the highest quality fruits are processed and the product is purified from poor quality or harmful components. This also guarantees the taste and nutritional value of the fruit juice that will be offered to the end consumer.

Pre-heater: Technology That Improves the Quality of Fruit Juice

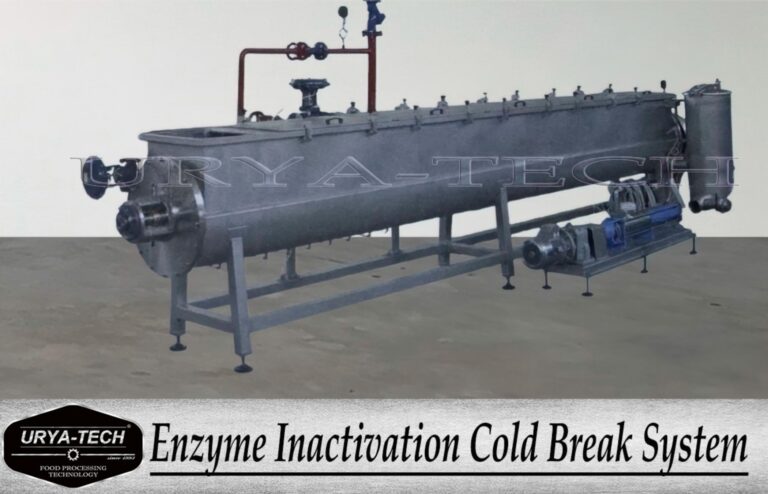

Enzyme activity has a significant impact on juice production. After freshly pressing the fruit, the enzymes become active, which can deteriorate the quality of the juice. The enzyme inactivation system comes into play to solve this problem. This system, which eliminates the effect of enzymes, helps the juice stay fresher for longer and preserves its nutritional value.

Preheaters control the temperature level of the juice and ensure that the enzymes become inactive. This is a critical step, especially for businesses that want to extend the shelf life of their juice and improve the quality of the product.

Volumetric Filling Machine: Precise and Fast Bottling

Another important part of the juice production line is the volumetric filling machine. This system ensures that the juice is filled into bottles or cans in exactly the right amount and with high accuracy. Volumetric filling machines guarantee that the product is filled in the right amount, which ensures that consumers receive the same amount of product.

These systems work automatically and speed up the bottling process. In addition, volumetric filling machines provide flexibility to manufacturers by offering different volumes of bottles or packaging options. In this way, production can be made in accordance with different market demands.

Pasteurization and cooling tunnel system: Food Safety and Shelf Life

Pasteurization is an extremely important step in the juice production line. This process heats the juice to eliminate harmful microorganisms. The cooling tunnel system comes into play after the pasteurization process. This system allows the juice to be cooled quickly and prevents temperature changes from damaging the product.

The combination of pasteurization and cooling tunnel systems ensures the food safety of the product and extends its shelf life. In addition, these systems produce fresh and healthy juice by preserving its nutritional value. The content of the juice can be stored for a long time without spoiling, which is an important advantage for businesses.

Choosing the Right Machine for Efficient and High Quality Fruit Juice Production

The juice production line offers producers great advantages in terms of efficiency, quality and speed. Each machine plays a major role as part of the production process and allows work to be done faster and more hygienically. From the Z-type conveyor to the pasteurization and cooling tunnel, each technology helps businesses reduce costs and increase product quality.

A juice production line equipped with the right machines increases the competitive advantage of businesses and allows them to offer fresh, natural and healthy products to consumers. If you are also producing fruit juice, you can both increase your efficiency and strengthen your position in the market by installing a production line equipped with quality machines.